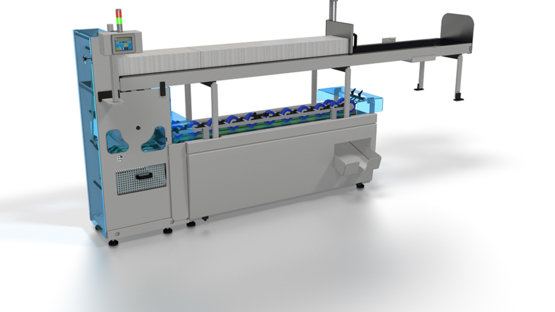

CMC 400 Series

The CMC 400 Series proudly introduces the new CMC Mailer Direct brand

A portfolio of solutions that preserve CMC’s software and hardware inserting tradition while enhancing communication capabilities. Improved economy and smaller footprint.

Optimized design. Rotary feeders are equipped with double grippers, transport chain pitch is reduced allowing a maximum rate of up to 22,000 envelopes per hour.

Innovative and simple insertion area inserts collated documents into the envelope and then drives the envelope to the output with a single continuous motion transport.

CMC 400

Cut Sheet, Continuous Feed and Combined input options.

Navigator controller offers database management, advanced matching, selectivity and printing support, mailpiece and event logging.

Heavy Duty construction withstands the demands of the direct mail industry. Designed to be maintained and repaired with in-house staff, eliminating the need for costly service contracts.

Available with a variety of feeder options, including rotary vacuum, shuttle, friction and rotary with separation disk for end fold applications.

The new, on-edge Conveyor design optimizes footprint and reduces labor cost.

Vacuum belt output table for straightforward installation of ink-jet addressing systems.

No stop (automatic rejection of errors) and flip-flop (allows the same product to be loaded in multiple feeders) system management functions ensure the highest efficiency.

CMC 400Evolution

This operator-friendly inserter uses simple and easy-to-use setup enhancements, such as toolless adjustments throughout the system, allowing quick format and size changes by the operator. Complete job changeovers can be accomplished within minutes. Reduced complexity for operators means less downtime and higher productivity.

The machine can be interfaced with any CMC Input Channel. CMC Input channels provide document processing from either cut sheet of continuous form input for high volume applications. Options are available to handle a wide range of applications, from low to high page counts, folding, stitching, 1UP, 2UP continuous form and DS (Dynamic Sequencer). All input channels are constructed to match the same 24/7 operation, high reliability, high efficiency and low maintenance of the base system to which they are connected.

- Hopper height allows easy loading with high insert stack

- Optional autoloaders for envelope feeder and insert feeders to reduce loading frequency

- Touch panel control for set-up

- Format changes can be made in under 5 minutes with easy toolless adjustments

- Automatic rejection of collation errors keeps system running

- Tracking control for each document

- New On-Edge Conveyoroes not require skilled operators

- the operator can collect the envelopes from either side

- the same operator can load and collect the envelopes

- in case of 2 mirrored lines 1 operator only is required to collect finished envelopes

CMC 400

- Minimum Envelope Format 100 x 180 mm

- Maximum Envelope Format 160 x 300 mm

- Maximum Collation Thickness 10 mm

- Maximum production speed 22.000 envelopes/hour

- Maximum thickness 10 m

CMC 400Evolution

- Minimum Envelope Format: 100 x 185 mm

- Maximum Envelope Format : 330 x 235 mm

- Maximum Collation Thickness: 10 mm

- Maximum Mechanical Speed CMC 400Evolution V1 : 25.000 pc/h (DL) – 15.000 pc/h (C6/C5) – 12.000 pc/h (C4)

- Maximum Mechanical Speed CMC 400Evolution V2: 21.000 pc/h (DL) – 18.000 pc/h (C6/C5) – 10.000 pc/h (C4)

If you would like further information, you can download our product brochure by filling in the form: