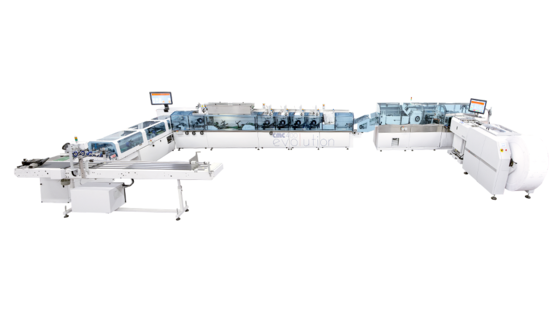

CMC 9000

Patented insertion area increases speed to 30,000 envelopes per hour by pre-staging the envelope to be inserted

Simplicity in the design is maintained where a single continuous motion inserts collated documents into the envelope and then drives the envelope to the output with a single continuous motion transport.

Extra capacity envelope hopper increases operator efficiency.

Heavy Duty construction guarantees long lasting 24/7 performance.

Testimonials

Available with a variety of feeder options, including rotary vacuum with double grippers, shuttle, friction and rotary with separation disk for end fold applications.

Vacuum belt output table for straightforward installation of ink-jet addressing systems.

No stop (automatic rejection of errors) and flip-flop (allows the same product to be loaded in multiple feeders) system management functions ensure the highest efficiency.

Cut Sheet and Continuous Feed input options.

Available with a variety of output options, including simple conveyor, automatic stacker for bundling and on-edge envelope stacker.

PC_ADD Line Controller offers database management, advanced matching, selectivity and printing support, mailpiece and event logging.

- Hopper height allows easy loading with high insert stack

- Touch panel control for set-up

- Format changes can be made in under 5 minutes with easy toolless adjustments

- Automatic rejection of collation errors keeps system running

- Tracking control for each document

Minimum Envelope: 100 (L) x 160 (W) mm

Maximum Envelope 160 (L) x 250 (W) mm

Maximum Mechanical Speed:

30,000 env/hour (DL)

26,000 env/hour (C5)

If you would like further information, you can download our product brochure by filling in the form: