CMC Genesys Compact

Your compact solution for smarter, sustainable and scalable packaging

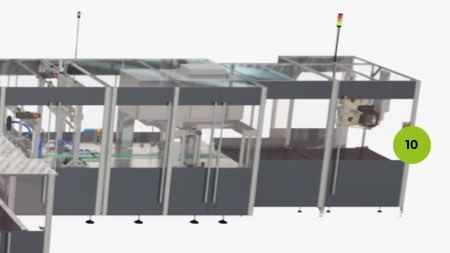

The CMC Genesys sets a new standard in packaging innovation with its optimized footprint, requiring just one-third of the floor space compared to other 3D packaging technologies on the market.

This compact design translates into significant cost savings by reducing the real estate required per square meter, allowing businesses to maximize their facility operational efficiency.

The streamlined footprint also makes installation straightforward and minimizes downtime.

Whether expanding, relocating, or adapting to evolving needs, the CMC Genesys can be easily repositioned, offering unmatched flexibility for dynamic operations. Its adaptability makes it particularly well-suited for smaller warehouses, where every square meter counts, enabling the implementation of advanced packaging technology without compromising valuable storage or workflow areas.

Compact, cost-effective, and versatile, the CMC Genesys is designed to optimize your packaging processes while preparing your business for future growth.

CMC Genesys Compact: Smarter, Sustainable, and Scalable Packaging in a Compact Design

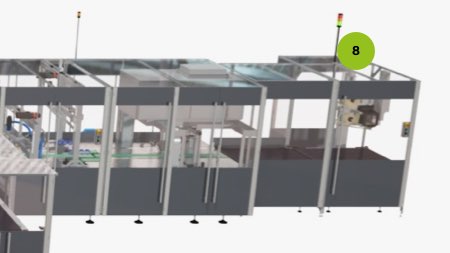

The CMC Genesys Compact is a game-changing solution that merges innovation, sustainability, and versatility in a space-efficient, cost-effective design. Tailored for the evolving demands of logistics and eCommerce, this compact packaging system delivers the performance of larger systems with a significantly smaller footprint, simplifying installation and enhancing ease of relocation when needed.

The Genesys Compact optimizes your packaging process by seamlessly handling both single and multi-line orders.

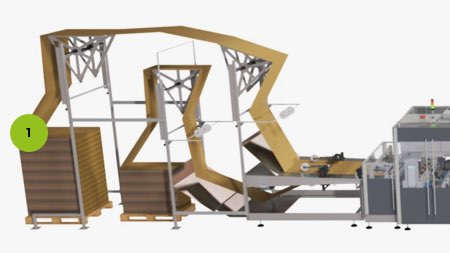

1. Order Induction: Orders are fed onto the induction module, ready for processing.

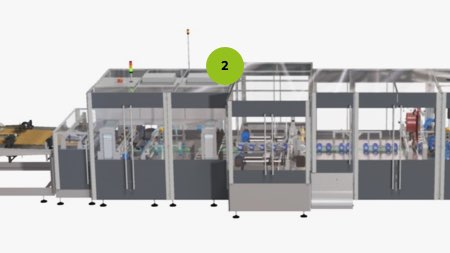

2. Precision Scanning: A barcode scanner quickly identifies each order, ensuring accuracy.

3. Cubing and Sizing: The system uses advanced cubing technology to measure and size each order, preparing it for the right-sized packaging solution.

4. Cardboard Input: The required cardboard is automatically fed from the input channel.

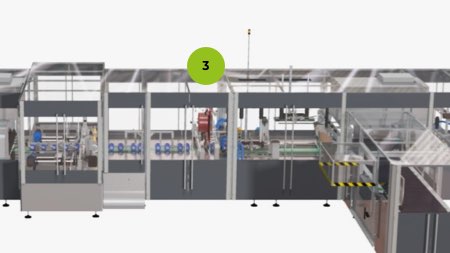

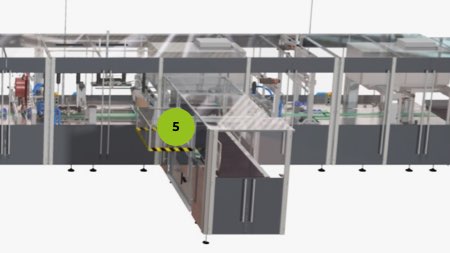

5. Precision Cutting and Scoring: A plotter-based system cuts the flat sheet to size and scores it for perfect folds.

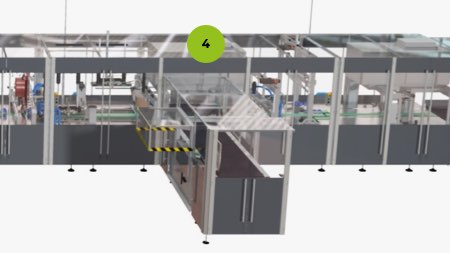

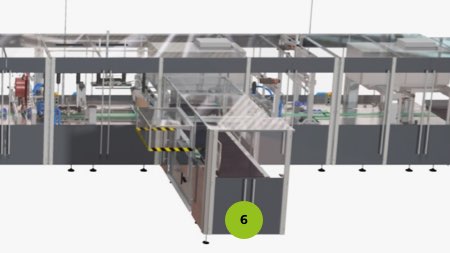

6. Box Formation and Filling: The pre-formed box is folded, the order is inserted, and the box is securely sealed using hot melt glue.

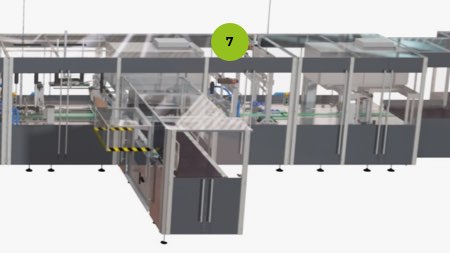

7. Labeling and Dispatch: A print-and-apply system attaches an address label to each package, making it ready for dispatch.

BENEFITS

SMALLER FOOTPRINT, OPTIMIZED EFFICIENCY

With a compact 44 sqm footprint, the CMC Genesys Compact maximizes your return per square meter, making it an ideal solution for facilities with space constraints.

SIMPLIFIED INTEGRATION & SCALABILITY

The CMC Genesys Compact features a modular design that ensures seamless operational integration. It is easy to install, relocate, and scale with additional features as your business grows. It’s perfect for smaller 3PLs Fulfilment Centers, SMEs, especially in industries with diverse packaging needs.

VERSATILE PERFORMANCE

The CMC Genesys Compact can handle single and multi-item orders, offering a minimum box thickness below 5 cm, eliminating filler, and enabling easy-open box styles for a superior customer experience.

SUSTAINABILITY AT ITS CORE

Its environmental footprint is significantly lower than that of the standard box process and aligns with its predecessor CMC Genesys. It achieves up to 58% fewer carbon emissions, 27.3% fewer cardboard usage, over 57% fewer volume per parcel, and up to 40% less corrugated waste.

SUSTAINABLE INVESTMENT

The CMC Genesys Compact modular design reduces moving parts and lowers capital and operational costs. Its durable construction ensures a long lifespan, reducing maintenance and replacement costs.

PRODUCT INTEGRITY

The inner folded edges securely hold various-sized multi-item shipments in place during transportation, eliminating the need for additional fillers.

EXCEPTIONAL CUSTOMER EXPERIENCE

The EASY-OPENING feature and optional reseal for returns enhance the customer experience, creating a memorable interaction while strengthening the brand.

CMC Genesys Compact can include a variety of ancillary equipment such as:

- Up to 4 fanfold channels

- Automatic products induct

- 6 sides automatic barcode readers

- Multiple label printers and application

- Check weigher

- Cam log

- Packvertizing

- Sorters

IT Integration

The CMC Genesys Compact is engineered for seamless integration with your WMS, WCS, and ERP systems, ensuring process integrity and optimized workflows.

This can be achieved via two modes:

Direct Connection to Wms

Through CMC’s native CIS protocol, enabling real-time communication via TCP/IP socket messages.

Integration via Cmc Middleware

Through a Middleware which acts as a translator, bridging the customer’s systems with CMC machines by converting data into the CIS protocol.

This approach ensures compatibility with any Data Management System.

CMC Dashboard

The CMC Dashboard empowers you to monitor, analyze, and optimize the performance of your CMC machines, available in two versions:

Dashboard - Live

■ Real-time monitoring of key performance indicators (KPIs) such as throughput, availability, and machine statuses.

■ Accessible via PC applications or web browsers

Dashboard - Web

■ Historical data analysis and trend tracking across multiple sites.

■ Features include customizable filters, advanced charting tools, and exportable reports for comprehensive insights.

With the aim of reducing waste and optimize processes, today our offer :

CMC GENESYS COMPACT :

- FANFOLD SPECS: from 600 mm to 1000 mm

- MINIMUM BOX: 270 x 210 x 48 mm

- MAXIMUM BOX: 560 x 380 x 290 mm

- MAXIMUM MECHANICAL SPEED: 500 boxes/hour

- FLUTE : Single wall B, single wall E, and double wall B/E

- THICKNESS : 1,2 mm – 4.0 mm

If you would like further information, you can download our product brochure by filling in the form: