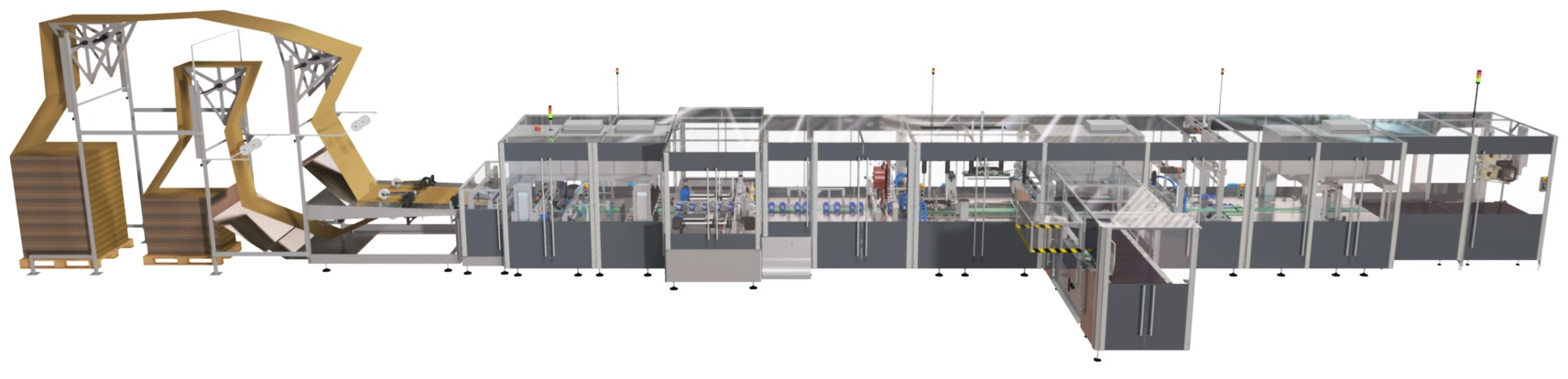

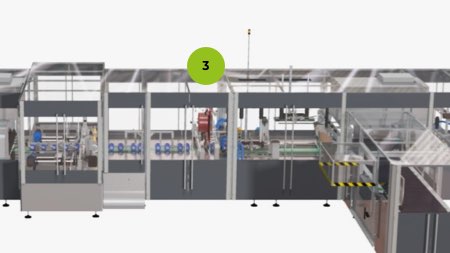

CMC CartonWrap Series

The revolutionary e-commerce packaging solution – every box fits to order with our flagship automated solution

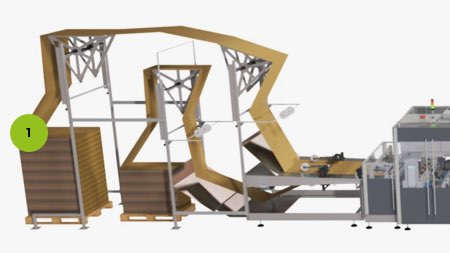

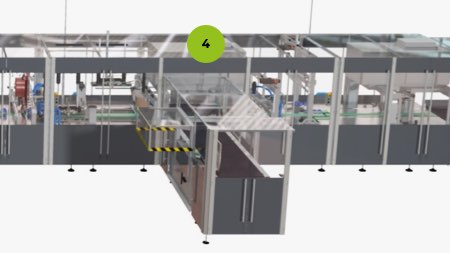

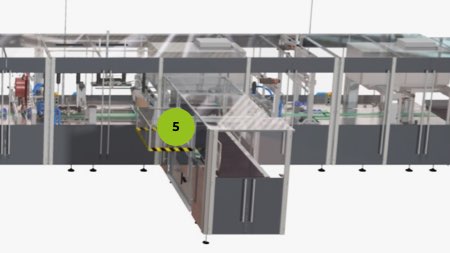

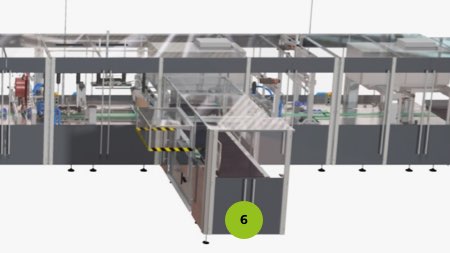

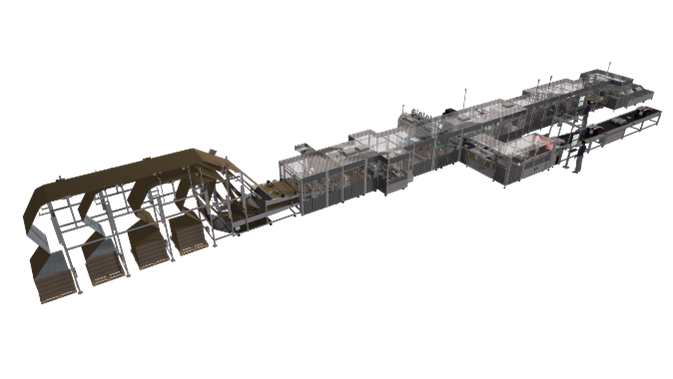

CMC CartonWrap is an automatic carton packaging system capable of creating custom boxes from fanfold-fed corrugated cardboard – meaning each box is perfect-sized to fit each order. The real-time format change is managed automatically through product recognition or directly from a database. This ensures high levels of flexibility and speed of processing, capable one box every 3.5 seconds.

As the most installed perfect-sized packaging machine in the world, we provide guaranteed robustness and protection with our boxes, no matter the order or size. The box build incorporates “bumpers” into the packaging to protect items from A to Z, and we can even strap larger boxes to further reduce risk of damage.

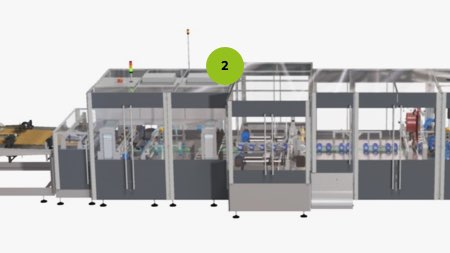

To optimize logistics, one or two labeling systems can be incorporated, according to shipping requirements. The packaging also offers easy unsealing and resealing for frictionless returns, and CMC CartonWrap can integrate with a printer to automate the folding and adding of printed invoices to an order.

The e-commerce sector is witnessing strong growth as more consumers shop online, a trend accelerated by COVID-19. Unsurprisingly, this trend is causing a significant uptick in the number of parcels being shipped to fulfil these online orders.

It has also increased competition within the e-commerce market and automation is key to staying ahead of the curve. In 2013 CMC identified this and decided to do something about it. Enter: CMC CartonWrap. This technology continues to disrupt the industry as the first 3D perfect-sized packaging machine, significantly reducing delivery times and volumes shipped.

Our fully automated solutions allow for ease of scaling operations while ensuring speed of delivery, something especially important to consumers and retailers.

The world’s leading retailers, e-commerce, and logistics companies now rely on CMC CartonWrap to meet demand. Our perfect-sized packaging technology optimizes cost and efficiency and delivers high levels of personalization.

This innovative technology also helps clients to achieve their sustainability goals. In standard e-commerce packaging, 40% of shipped volume is empty space. This creates unnecessary waste and cost because needlessly high volumes are shipped, and also elevates transport-related CO2 emissions. Since 2013, CMC CartonWrap has revolutionized 3D packaging, creating custom sized boxes that minimize waste by reducing excess packaging and avoiding filler materials. The solution is also designed to use 100% recycled paper and low impact glue.

CMC CartonWrap also helps manage order complexity, seamlessly managing millions of different SKUs across a variety of orders. When demand rises during peak season, CMC CartonWrap delivers high speed packaging across a wide variety of box sizes. For this reason, our customers invest in the CartonWrap to help mitigate against labor shortages and guarantee reliability, without compromising on quality.

Customisation & integration

For greater customization, CMC CartonWrap can work with full color print systems for logos, trademarks, or any other information, applied directly to the box. Learn more about CMC Packvertizing here. It doesn’t stop there – the solution can also integrate feeders to selectively add any print marketing a customer may want to include, from leaflets to discount coupons.

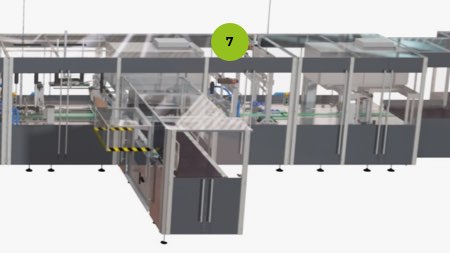

Crucially, CMC CartonWrap seamlessly integrates with your warehouse management system to process both single item and multi-line, pre-consolidated orders.

To take this customer favorite a step further, we have introduced a series of CartonWrap machines to meet any packaging need, with four market leading innovations that ensure we can reduce waste across a full range of custom box sizes. We are true pioneers in the perfect-sized packaging industry, producing the biggest and smallest automated boxes in the market.

Our latest innovation in the series features the CartonWrap XS which has been specially designed to accommodate smaller items such as consumer electronics, pharmaceutical and cosmetics products. With a box that is custom made according to product, the XS significantly reduces material costs, excess cardboard, and filler typically used when packaging small items.

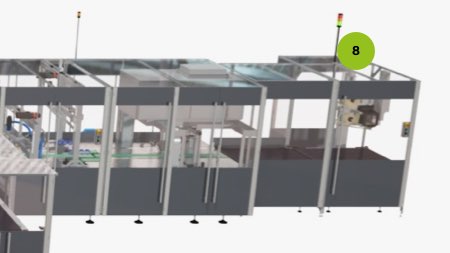

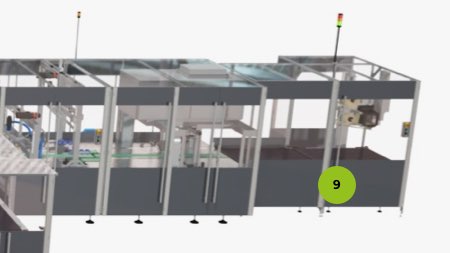

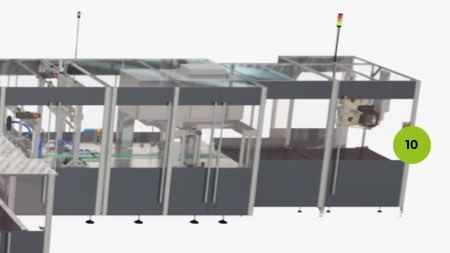

CMC CartonWrap series can include a variety of ancillary equipment such as:

- Up to 4 fanfold channels

- Automatic products induct

- 6 sides automatic barcode readers

- Invoice printers

- Selective enclosures feeders

- Multiple label printers and application

- Check weigher

- Cam log

- Packvertizing

- Sorters

With the aim of reducing waste and optimize processes, today our offer includes 4 CMC CartonWrap models:

CMC CARTONWRAP 1000:

- FANFOLD SPECS: from 600 mm to 1200 mm

- CUT SHEET SPECS: MAX W 1200 x L 2300 mm

- MINIMUM BOX: W 240 x L 150 x H 30 mm

- MAXIMUM BOX: W 600 x L 350 x H 200 mm

- MAXIMUM MECHANICAL SPEED: over 1.000 boxes/hour

CMC CARTONWRAP XS:

- FANFOLD SPECS: from 500mm to 1000mm

- CUT SHEET SPECS: MAX W 1000 x L 2300 mm

- WAVE LINE SPECS: MAX REEL WIDTH 1000 mm

- MINIMUM BOX: W 150 X L 100 X H 25 mm

- MAXIMUM BOX(WIDTH): W 600 X L 380 X H 160 mm

- MAXIMUM BOX(HEIGHT):W 450 X L 380 X H 215 mm

- MAXIMUM MECHANICAL SPEED: 900 boxes/hour

CMC CARTONWRAP L:

- FANFOLD SPECS: from 600mm to 1200mm

- CUT SHEET SPECS: MAX W 1200 x L 2300 mm

- WAVE LINE SPECS: MAX REEL WIDTH 1200 mm

- MINIMUM BOX: W 240 X L 150 X H 30 mm

- MAXIMUM BOX(WIDTH): W 600 X L 400 X H 215 mm

- MAXIMUM BOX(HEIGHT): W 500 X L 400 X H 270mm

- MAXIMUM MECHANICAL SPEED: 900 boxes/hour

CMC CARTONWRAP XL:

- FANFOLD SPECS: from 800 mm to 1400 mm

- CUT SHEET SPECS: MAX W 1200 x L 2300 mm

- WAVE LINE SPECS: MAX REEL WIDTH 1400 mm

- MINIMUM BOX: W 250 x L 160 x H 35 mm

- MAXIMUM BOX (MAXIMUM WIDTH): W 800 x L 600 x H 215 mm

- MAXIMUM BOX (MAXIMUM HEIGHT): W 490 x L 600 x H 370 mm

- MAXIMUM MECHANICAL SPEED: 900 boxes/hour

If you would like further information, you can download our product brochure by filling in the form: