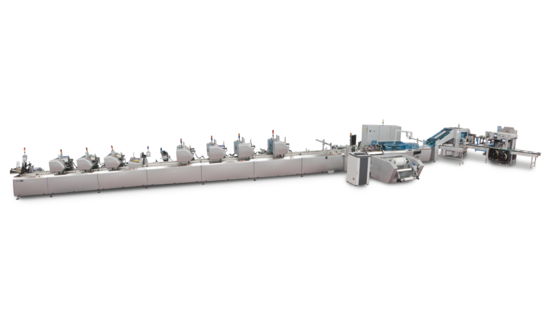

CMC 2800/3200

The CMC 2800 is the perfect film-wrapping system for the 21st century

This innovative fully servo-controlled system not only provides ultimate flexibility, but assures minimal set-up and changeover times, reduced maintenance through fewer moving parts, expandability through modular design; thus improving productivity and reducing cost of ownership.

The advanced controls and product tracking of the CMC 2800 make it the ideal solution for the most complex 'intelligent' jobs requiring reading, ink jet printing, selective feeding, matching, sorting, integration to upstream and downstream lines. Full system integrity is ensured with the addition of PC_Add Line Controller.

- Servo driven shuttle feeder for rigid and thick products

- Sliding and pivoting Servo driven rotary vacuum drum feeder for the greatest feeding flexibility

- Optional first page opening devices for inserting products into main product.

- Thermo regulated cross and longitudinal sealers. Optional sealers for all available film types, including polypropylene films and biodegradable films. Optional side-sealing.

- Dynamic electronic servo driven cross sealer allows for high speed production

- Optional pre-printed film registration and labeling systems

- Available in wide body version to feed newspapers in 'landscape' orientation

- Standard version handles product thickness up to 40 mm. Enhanced version can handle products thickness up to 80 mm.

- Standard version cycles up to 25,000 pieces/hour. CMC 3200 adds a second longitudinal sealer to increase cycle speed to 30,000 pieces/hour

Formats

- Minimum: 100 x 120 mm

- Maximum: 300 x 430 mm

- Maximum thickness

- 40 mm

- 80 mm (optional)

Film Thickness

- 20 – 100 microns

Max Mechanical Speed:

- 25,000 pieces/hour (2800)

- 30,000 pieces/hour (3200)

If you would like further information, you can download our product brochure by filling in the form: