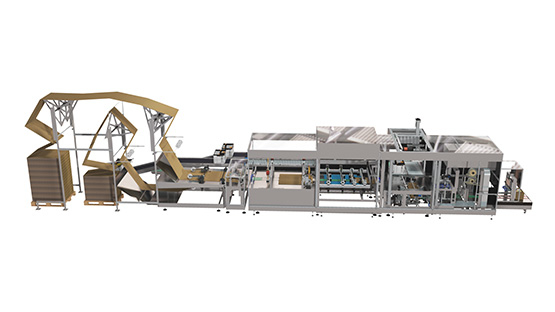

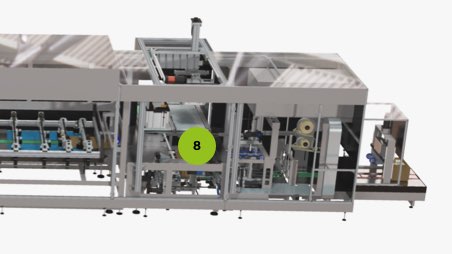

CMC Genesys Combo

FULLY AUTOMATED RIGHT-SIZED PACKAGING

CMC has introduced a new feature on the CMC Genesys to address our customers’ needs.

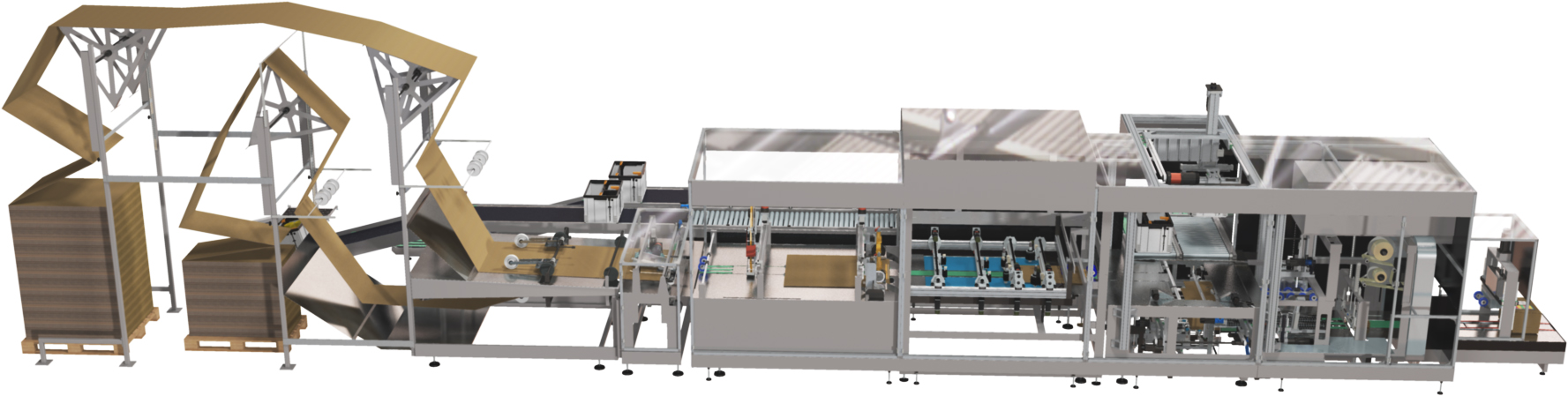

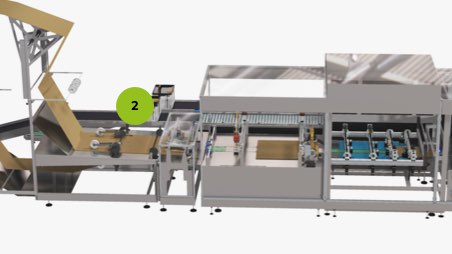

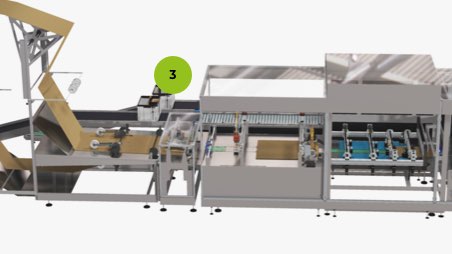

The new CMC Genesys Combo feature allows for the individual loading of both single-line orders and multi-line orders.

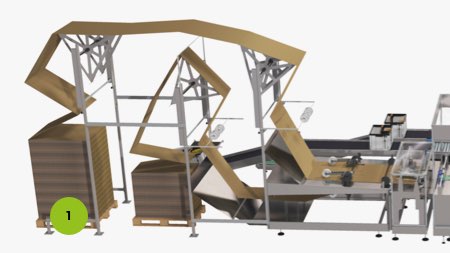

Like the standard version of the CMC Genesys, multiple orders are loaded through CMC Vary-Totes, the most efficient system for handling multiple orders to date.

The COMBO system adds the capability of loading single-line orders through a dedicated induct conveyor.

The CMC Genesys is the only auto-packer system that can be directly connected to a warehouse storage system through the CMC Patented Vary-Tote solution.

Orders are automatically picked and consolidated in the CMC Vary-Tote which is directly conveyed to the Genesys auto packing system, the ultimate solution for packaging automation.

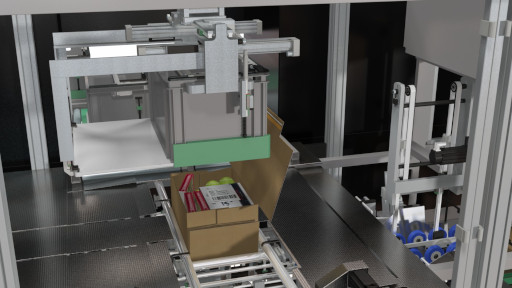

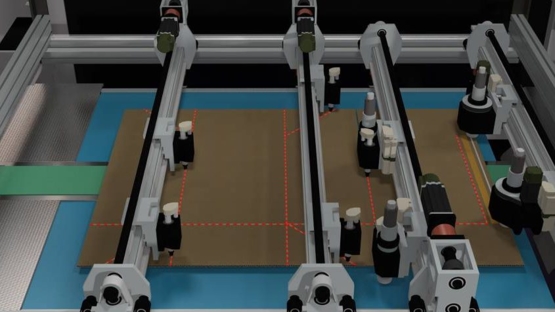

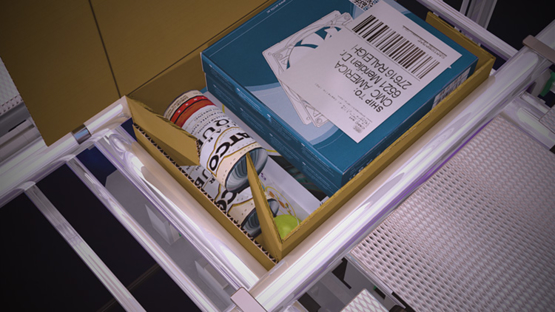

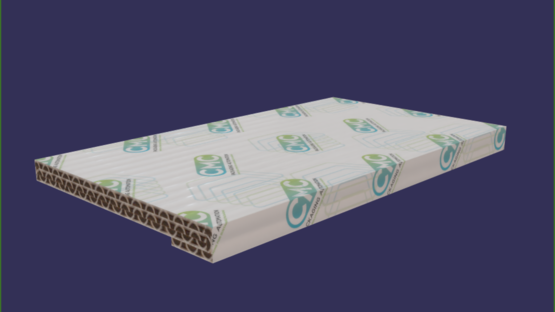

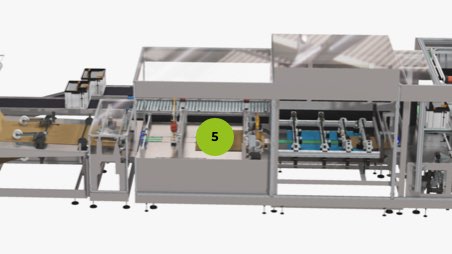

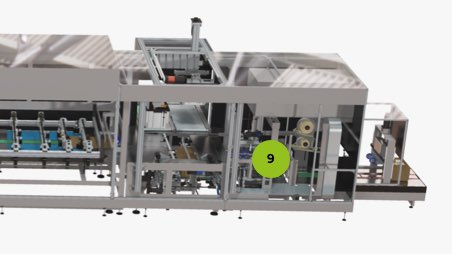

CMC Genesys creates a unique box structure that not only uses less corrugated than a standard regular slotted carton but also holds items in position removing the need for void fill. When the plotter cuts and creases the flat blank, trimmings aren’t cut out and discarded but folded inside the 4 corners of the box creating a stabilizing barrier for multiple items.

The customer experience is enhanced through the “easy open” and “resealable strip”, as the same box can also be used for returns.

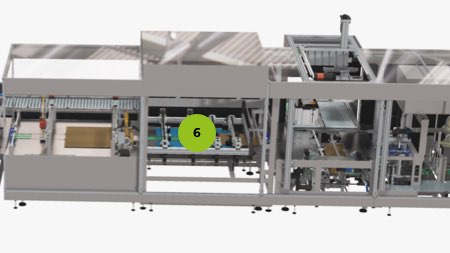

True of CMC automated packaging solutions,Genesys saves on labor, freight/box volumes and corrugated consumption. The adjustability of the Vary-Tote eliminates needless offline operations and WMS accuracy allowing for increased throughput and productivity.

CMC Genesys is the only auto-packer that can be directly connected to a warehouse storage system through the CMC Patented Vary-Tote solution.

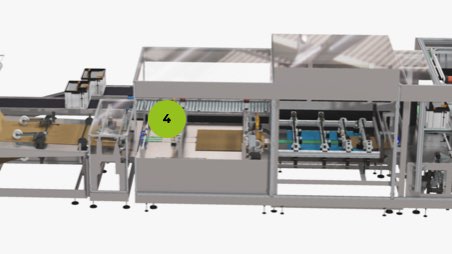

Picked items are placed inside the Vary-Tote which features two inner adjustable guides used to compact the selected items to the minimum possible volume.

This adjustment, which will be scanned at the CMC Genesys inlet, will determine the dimension of each box which will be unique to each individual consignment.

This innovative concept is particularly well-suited for picking and packing multiple regular or irregular shaped items within a size range without the requirement to be strapped or wrapped together.

OUTSTANDING TECHNICAL FEATURES

• Multi-line orders are fulfilled without pre-consolidation

• No need to strap or wrap items together

• Single workflow for both singles and multis

• Digital cutting requires less maintenance than mechanical systems

OUSTANDING MATERIAL AND PROCESS SAVINGS

• Labor savings by eliminating any human loading and operations

• Less corrugated consumption

• Improved shipping costs with less volume shipped

• Eliminates any void filling material

OUTSTANDING CUSTOMER EXPERIENCE

• Exceptional box strength

• Improved customer experience with

• easy-opening resealing and Packvertizing

• Lower environmental impact

• Multi-channel ready

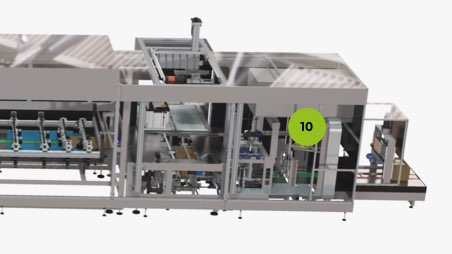

- FANFOLD SPECS: from 600mm to 1000mm

- BOX DIMENSION Minimum-Maximum:

- H= 60mm 290mm

- L= 210mm 380mm

- W = 270mm 560mm

- MAXIMUM MECHANICAL SPEED: 850 boxes/hour

If you would like further information, you can download our product brochure by filling in the form: