CMC Genesys

The next generation 3D box on demand machine

The rise of e-commerce is fuelling packaging production and its environmental impact. By 2026, 7,000-8,300 parcels will be shipped across the globe every second.

In e-commerce, multi-line orders represent 60% of total shipments, requiring more processing time and manual labor to pre-consolidate orders. More complicated orders are often split, increasing unnecessary packaging and shipping costs.

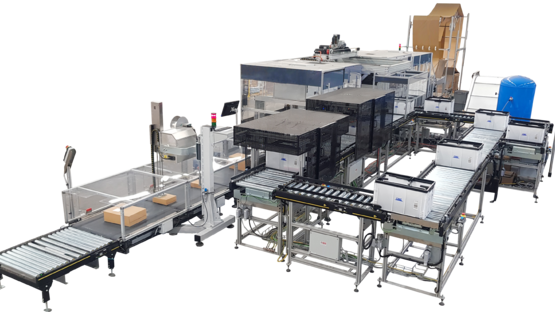

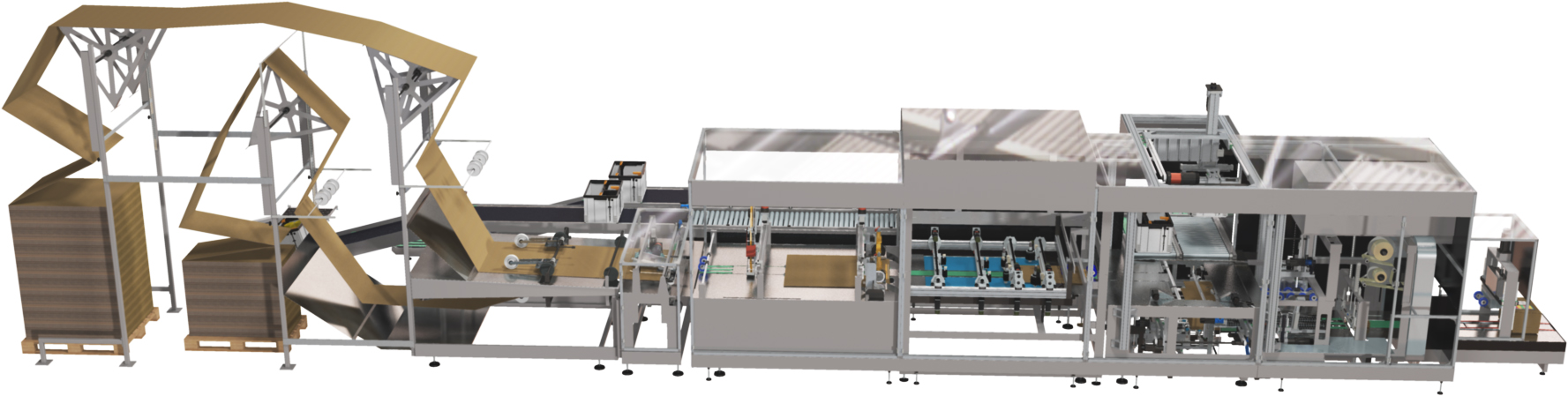

CMC Genesys is the ultimate automated solution for high volume, multi-line orders. We named the new system Genesys as it is the next generation of technology that redefines this type of packaging. The new fully automatic technology delivers orders in perfect-sized, sustainable boxes without any human loading or pre-consolidation for multi-line orders.

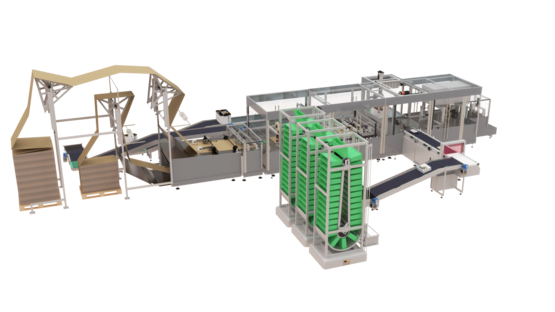

CMC Genesys Combo

Fully automated right-sized packaging

CMC has introduced a new feature on the CMC Genesys to address our customers’ needs.

The new CMC Genesys Combo feature allows for the individual loading of both single-line orders and multi-line orders.

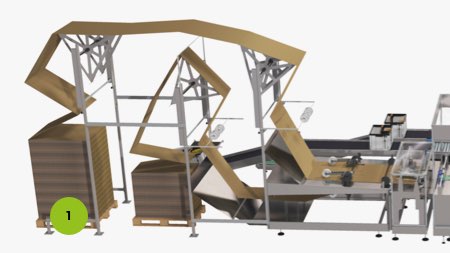

Like the standard version of the CMC Genesys, multiple orders are loaded through CMC Vary-Totes, the most efficient system for handling multiple orders to date.

The COMBO system adds the capability of loading single-line orders through a dedicated induct conveyor.

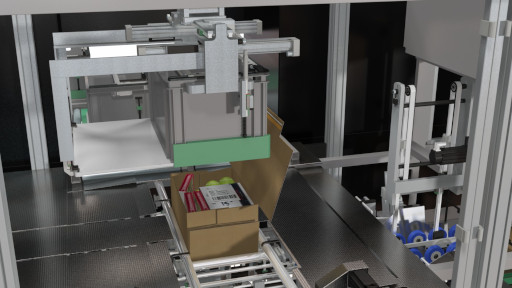

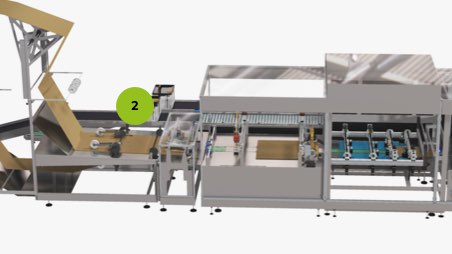

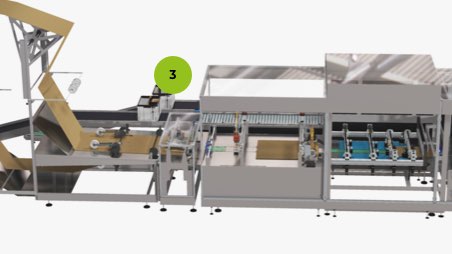

CMC Genesys is the only auto-packaging solution that can be directly connected to warehouse storage and picking area. This is possible due to CMC Vary-Tote, a proprietary technology that allows the user to pick single or multi-SKUs in the same stream. CMC Vary-Tote adjustable inner guides correctly size each order to determine the unique dimension of every box. This innovative concept feeds and packs multi-line orders and irregular shaped products without strapping or wrapping together items - so there is no need for pre-consolidation.

From here, the CMC Vary-Tote is automatically inducted into the CMC Genesys machine.

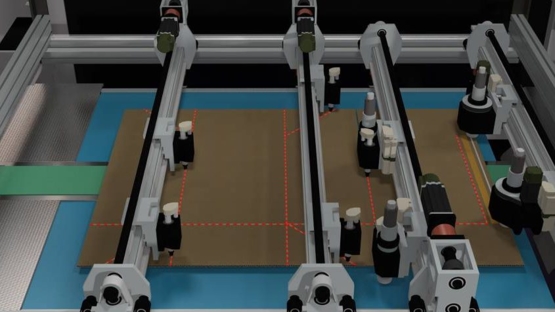

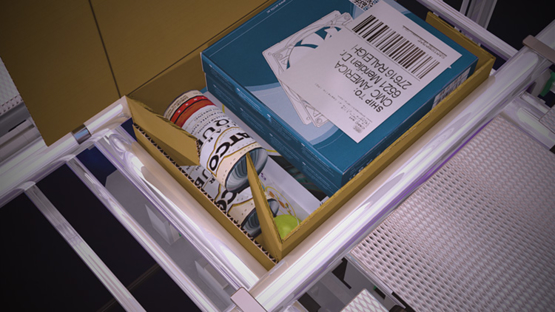

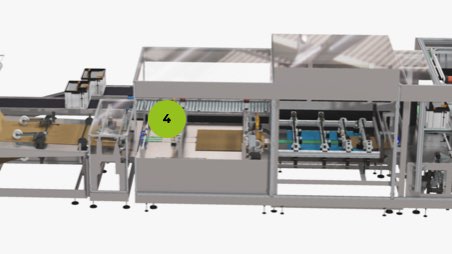

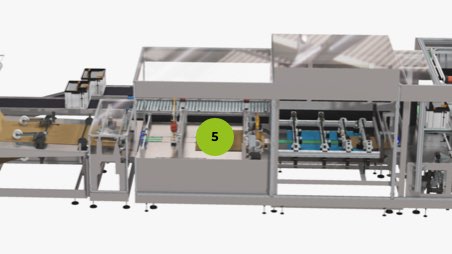

CMC Genesys creates a unique box structure by using a plotter to cut and crease the exact box template. This uses less cardboard than standard regular slotted cartons and holds items in position without void filler. When the plotter cuts and creases the flat blank, trimmings aren’t cut out and discarded, but folded inside the 4 edges of the box, creating a containing barrier for multiple items. Giving even stronger boxes than previously possible.

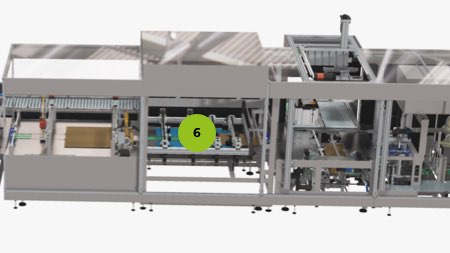

The end customer experience is enhanced by the innovative “easy open” box with a “resealable strip”, meaning the same box can also be used for returns. Boxes are safely sealed with low impact glue rather than tape and the mono-material approach for the whole pack makes recycling easier. Smaller boxes mean higher truck density and less C02 emissions across last mile logistics.

With CMC Packvertizing 1: 1 full color print customers have the unique opportunity to further excite and enhance the overall customer experience by adding logos or special messages, either inside or outside the box.

The CMC Genesys can also produce a ‘Classy’ box. This box is an oyster-style opening box, specially designed for luxury items, where customers require a premium user experience.

CMC Genesys dramatically reduces labor costs, shipping volumes and cardboard consumption. And as demand rises, the system keeps pace by eliminating needless offline operations, maintaining high speed, productivity, and quality.

- Improved shipping costs with less volumes shipped

- Less environmental impact

- No void fills and less cardboard consumption

- Multi-line orders are fulfilled without pre-consolidation

- No need to strap or wrap items together

- Single workflow for both single and multi-line orders

- Dynamic corrugated cutting requires less maintenance than mechanical systems

- Labor saving via reduced human loading and errors

- Improved customer experience

- Exceptional box strength

- FANFOLD SPECS: from 600mm to 1000mm

- BOX DIMENSION Minimum-Maximum:

- H= 60mm 290mm

- L= 210mm 380mm

- W = 270mm 560mm

- MAXIMUM MECHANICAL SPEED: 850 boxes/hour

If you would like further information, you can download our product brochure by filling in the form: